Products Description

This device is a laboratory testing instrument used to determine the viscosity characteristics of asphalt and asphalt-related materials under medium and low temperature conditions. The instrument employs the capillary flow principle, driving the sample to flow stably within a capillary tube via vacuum or reduced pressure. It measures the outflow time and calculates the viscosity value, effectively reducing the influence of air bubbles and volatile factors on the results.

Vacuum decompression capillary viscometer

Model:TDSM-305

I.Standards Met

JTG E20"Test Procedures for Asphalt and Asphalt Mixtures in Highway Engineering"and T0620-2011"Dynamic Annual Test of Asphalt(Vacuum Capillary Method)"

People's Republic of China Petroleum and Chemical Industry Standard SH/0557-1998"Petroleum Asphalt Viscosity Determination Method(Vacuum Capillary Method)"

GB/T265-88"Petroleum Products:Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity"

ASTM D2171/D2171M-22"Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer"

II.System Composition

Constant Temperature Water Bath System:Includes a glass tank,heating device,temperature controller,and stirrer,ensuring precise and stable test temperature.

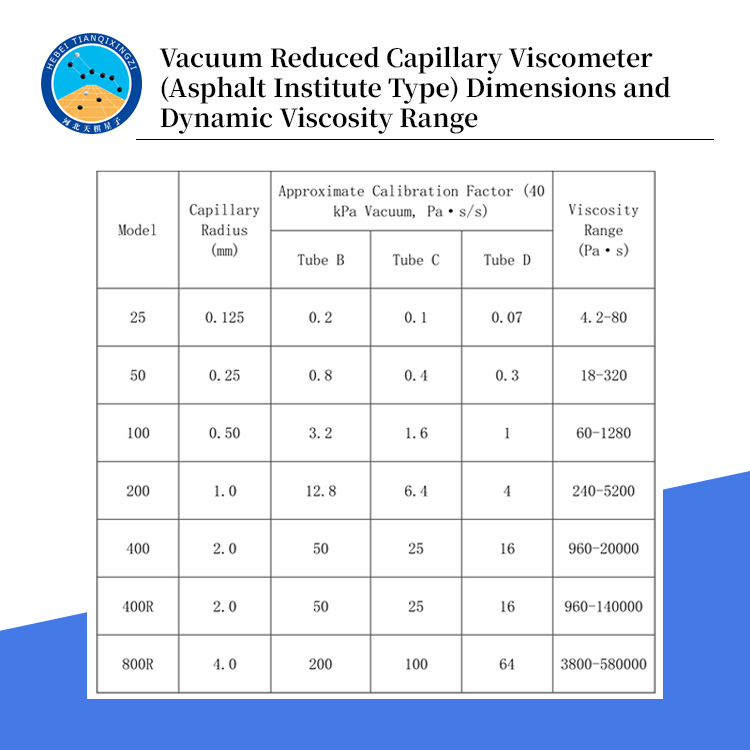

Capillary Assembly:A set of three capillary tubes of different specifications;the appropriate model can be selected according to the sample viscosity.

Vacuum pressure reduction system:Composed of a vacuum pump,pressure sensor,control valve,etc.,maintaining a constant vacuum environment.

Timing system:A high-precision timer automatically records the time it takes for asphalt to flow through the capillary scale.

Control system:A 5-inch LCD screen with an embedded microprocessor enables human-machine interaction and data processing.

Printing output system:Built-in mini printer,which can directly print test reports and historical data.